I recently received an email from a quality cable maintenance technician. He stated the following:

Maybe I missed it, but I’ve never seen a good column on the resistance bridge feature. It is the best time saver there is when used properly, especially when using it in the field by yourself. It can help you get a good idea where the trouble is as opposed to having to be dead wrong when digging up a street or someone’s front yard. Any tricks and tips would be appreciated.

Thank you,

Tim Segada

The resistance fault locating feature (RFL) in the multi-function test set is a constant current application of the Wheatstone bridge that measures the distance to cable faults such as a short, a ground, or crossed battery on a cable pair, or a cable pair.

The 2 instances where the RFL feature shines are:

1. When there is a single pair fault in an aerial closure or buried pedestal or in a section of cable between 2 aerial terminals or

2. When there are 2 buried pedestals where several pairs are faulted because of water in the section, a splice full of water, or physical damage from shovels, stakes, back hoes, etc.

Rather than using the RFL feature, many field technicians are directed by their management teams to reactively troubleshoot by using the divide-and-conquer method where they go half way along the cable route and cut the pair in half to determine which way to go to find the trouble. Alternatively, they move circuits to another cable pair rather than proactively identify the root cause of the pair fault.

Sustainable approach to fault locating with RFL

Let’s start with the single pair fault. Here’s an example:

A customer complains of no dial tone, static, and no modem sync, because the tip side of the cable pair is pinched by the pedestal lid because of recent activity by another technician working in that terminal.

Stopping at the cross-box next to the remote and testing the circuit shows a 10,000-ohm tip ground, and the ring conductor tests clear. This is an ideal time to use the single pair hookup using the resistance bridge feature to find the distance to the trouble.

Go ahead and strap the pair by shorting the tip to ring. In ready access plant do not skin the insulation and twist the pair together. That is not a 0-ohm strap, and it will eat your lunch. Use an IDC connector such as a PICKABOND connector or a 3M Scotchlok connector.

If testing at the customer’s terminal proves the fault is in the cable between the remote and the customer’s terminal, select the single pair hookup in the RFL feature.

When running the RFL feature, the test set measures the resistance to the far end strap in ohms. The test set then runs current through the fault. Depending where the fault is located, a percentage of the current runs from the fault to the test set for a resistance to the fault (RTF) in ohms, and a percentage of current to the far end strap to fault for a far end resistance (RSTF) in ohms.

For this example, let’s say these are your results:

• DTS 300 ohms from the test set to the far end strap

• DTF 100 ohms from the customer’s terminal to the fault

• STF 200 ohms from the far end strap to the fault

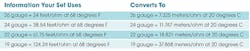

While your RFL feature automatically provides the correct cable gauge and cable temperature, here is the information your set uses and how it’s converted:

I believe that if every technician could learn the following process for locating single-pair faults with a RFL, every company would save a lot of technician time in the field and save LOTS of money!

Resistance fault locator single-pair fault locating process

In our above example the trouble is 200 ohms from the far end strap and 100 ohms from the customer’s terminal going toward the remote. Let’s assume that the cable is a 26-gauge cable at 58 degrees. The RFL feature would show the following: a distance to strap (DTS) of 7,200 feet; a distant to fault (DTF) of 2,400 feet; and strap to fault (STF) 4,800 feet.

• Proceeding along the cable route toward the cross-box, we find a pedestal that is closest to 2,400 feet DTF. While this may be the exact location, we might simply be "close", so we have to determine the precise location of the trouble.

• Remember that the fault is at 200 ohms from the strap at the cross-box. Set the RFL to ohms.

• If the RTS were to measure 200 ohms, the trouble is right there.

• If the RTS were to measure 180 ohms, we didn’t go far enough. Twenty (20) ohms more at 24 feet per ohm would put the fault 480 feet farther toward the customer.

• If the RTS were to measure 220 ohms, we went too far. Go back toward the cross-box 20 ohms or 480 feet.

So simple, but surprising how often this easy process isn’t implemented.