Interference From Solar and Wind Power on Copper Cable Facilities —

As Green Energy power generation becomes more prevalent, interference (metallic noise) has become an ever-increasing problem for services provided over copper communications facilities. Harmonics found in wind farm and photovoltaic (PV) solar farm collector systems, that are induced into copper communications cables, may cause audible noise on communications circuits such as Plain Old Telephone Service (POTS) lines.

What Are AC Harmonics?

The fundamental frequency of the AC power system in the US is 60Hz. Conditions in the power system, such as non-linear loads, can create harmonic distortions in the 60Hz sine wave which are in multiples of 60Hz (e.g.,120Hz, 180Hz, 240Hz, etc.). For analog circuits, line termination equipment has a C-Message weighted filter which greatly reduces the effects of the fundamental frequency. Since the human ear can generally hear up to 20K Hz, any harmonic induced at a great enough magnitude can be heard as audible noise on POTS and on other analog communications circuits.

For the purpose of this article we need to understand how AC power is produced by wind and solar PV generation. Any device (rectifier or inverter) that converts voltage, AC-to-DC or DC-to-AC, creates harmonics due to how the conversions takes place.

InvisiLight® Solution for Deploying Fiber

April 2, 2022Go to Market Faster. Speed up Network Deployment

April 2, 2022Episode 10: Fiber Optic Closure Specs Explained…

April 1, 2022Food for Thought from Our 2022 ICT Visionaries

April 1, 2022Following are 2 situations that illustrate the problem and outline a solution.

Situation 1: Photovoltaic Solar Farm Inverters

PV Solar Farm generation utilizes DC-to-AC inverters which change the DC voltage generated by the photovoltaic panels into AC voltage (60Hz in the US). Each solar farm is built in multiple "pods"; each equipped with an inverter. Each inverter’s AC output is tied to a collector system. Note that each inverter may create harmonics that are added into the collector system. The collector system is run through one or more "step up" transformer(s) which brings the solar farm generated AC voltage to the line voltage level at the power company point of interconnect.

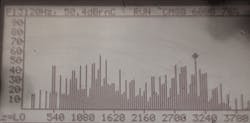

Depending on the "pulse" rate of the inverter, (6,12, 24, etc.) the harmonic distortions propagated into the AC power system will be different but equally detrimental to the analog circuits on the copper communications cables. In my investigation into a solar farm suspected of producing harmonic distortions, the 47th and 49th harmonics were discovered to be the primary cause of noise in the copper communications cables. Figure 1 shows a screen shot of a spectrum analyzer terminated on a copper cable pair associated with a customer noise complaint.

Figure 1. Solar Farm Harmonic Graph, Peak Harmonics at the 47th and 49th.

Situation 2: Wind Turbine Generators

Due to the inconsistent speed of the wind, Wind Turbine Generators (WTG) go through a more complex conversion to stabilize the output power from each turbine. Initially, wind-powered generators produce an AC voltage. This AC voltage then goes through a rectifier/inverter, AC-to-DC/DC-to-AC conversion which stabilizes the voltage and establishes the 60Hz sine-wave. This system will produce harmonics in the AC collector system of a wind farm.

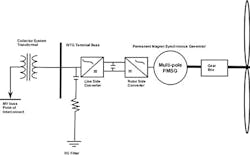

Wind farm generators are equipped with filters that may reduce the overall quantity of harmonics that will appear in the AC collector system. In all the excessive noise cases I have investigated associated with wind farms, the 13th harmonic (780Hz) was always the predominant source of the metallic noise present on copper communications cables. Figure 2 helps to illustrate the dual voltage conversion.

Figure 2. Illustration of WTG Dual Voltage Conversion and RC Filter for Mitigation of Harmonics Caused by Voltage Conversions.

Mitigation

Now that we have a better understanding of how the AC harmonics are created by these forms of power generation, what can be done to mitigate the problem? Assuming that basic testing of the cable pairs has been completed and all resistive and capacitive faults have been cleared, the first step for any noise mitigation in communications cables is grounding and bonding the cable shield. This is essential especially where communication cables are placed in parallel to 1, 2, or 3 phase AC distribution lines or a 3 phase wind farm collector system.

Using a "clamp on" AC current meter placed around the cable bond strap, confirm that there is AC current flowing on the cable shields. How much current should be flowing is hard to determine. The fact that current IS flowing is what is most important at this point.

For most 60Hz harmonics, good shield current will usually mitigate most noise issues caused by excessive harmonics. In all but one of the cases of wind farms I have been involved with, once we established good shield current, there was enough cancelling effect to reduce the noise on customer lines to below 20 dBrnc. In one case, we were not able to obtain a low impedance path for shield current so an Induction Neutralizing Transformer (INT) was installed which mitigated the harmonics and reduced the noise levels on the customers POTS lines.

Note: INTs are great devices to use to mitigate lower frequency harmonics like the 13th when standard grounding and bonding methods are not sufficient. INTs, however, can be expensive to place especially for cables over 100 pair. Products manufactured for noise mitigation, such as the INT, are not designed to treat higher harmonic frequencies in the range of the 49th harmonic.

If, after verifying shield current is present on all cable shields, the noise levels are still too high (above 20 dBrnc), a spectrum analyzer will need to be used to determine the offending harmonic frequency(s). As previously stated, wind farms appear to produce harmonics at or around the 13th harmonic, while solar farms may produce harmonics around the 47th and 49th.

Teamwork

When troubleshooting metallic noise that is caused by power line harmonics, no matter the source, it is essential to engage the power provider(s) involved. For wind and solar facilities, the mitigation work may be up to the generator/inverter manufacturer. In my research for the solar farm, I was able to prove that the 8 inverters on the solar farm were the harmonic "producers". Due to the high frequency of the harmonics (again the 47th and 49th), I had no method or device that would mitigate the noise on the customers’ lines.

Together, the local power company, solar farm owner, and inverter manufacturer and our team, worked to devise a plan for mitigation. When all was said and done, the inverter manufacturer was able to make software adjustments to half of the inverters, which created a cancelling effect in the collector system. The end result was a complete elimination of noise on all customer lines in the vicinity of the solar farm. (See Figure 3.)

Figure 3. Harmonic Graph after solar farm inverters adjusted, showing all Harmonics reduced.

It is essential that technicians understand that it is up to them when dealing with high power influence. They must troubleshoot the AC power system, and take those findings back to the power company. Surprisingly, in many cases, the power company doesn’t even know there is anything wrong.

Like this Article?

Subscribe to ISE magazine and start receiving your FREE monthly copy today!

As outside plant technicians, you MUST be able to work with other utilities such as power companies, green energy producers, and equipment manufacturers, to resolve noise issues that arise in copper communications facilities.

About the Author