Latest from 5G/6G & Fixed Wireless Access/Mobile Evolution

The Inevitable Evolution to C-RAN

Cost-Efficient Deployment of Remote Radio Head Architectures —

Widespread implementation of 5G is expected by 2020 with Centralized Radio Access Network’s (C-RANs) at the heart of deployments. The C-RAN market is projected to grow to USD 1,1 billion by 2022, a CAGR of 10.7%. (Source: © 2009-2017 MarketsandMarkets Research Private Ltd.) C-RAN promises a reduction of CapEx and OpEx by reducing cell site infrastructure and sharing costs such as backup power and cooling/heating. The promise of load sharing across base band units (BBUs) and centralized maintenance provide additional CapEx and OpEx savings.

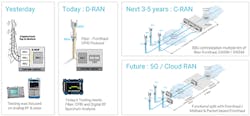

The transformation toward C-RAN starts with the separation of BBU and remote radio head (RRH), replacement of copper cables with optical fiber, and relocation of the RRH to the top of the tower. BBUs are then centralized into C-RAN hubs, up to 15-20 km away from the cell sites. Finally, virtualization of the network takes place. (See Figure 1.)

Figure 1. The evolution towards Cloud-RAN.

Significant increases in RRH deployment rates are expected as new and higher frequency bands are implemented and the ability to deploy new RRHs in a timely manner will be a major factor in achieving the promised savings. However, todays RRH deployment rates are falling short of expectations.

During cell construction, contractors lack the necessary tools to test cell site operation prior to handover to the Mobile Network Operator (MNO) for network integration. This leads to failed integration attempts and multiple visits for both the contractor and integration teams before a cell site becomes operational. The need for tower crews to fix problems associated with the RRH, co-ax jumpers, and Remote Electrical Tilt (RET) devices at the top of the tower further complicates matters. Delays associated with these failures mean that deployment rates of new or upgraded cell sites fail to meet MNO objectives, in turn leading to increased costs and lost revenue.

New Methods for RRH Deployment

Reducing the cost of cell site deployment and improving the deployment rate requires a fresh look

at the processes used during the deployment phase.In response, a 5-step validation procedure for cell site installation could help alleviate some of these challenges. (See Figure 2.)

Figure 2. The 5-step approach to validating mobile fronthaul networks.

A major new component supporting the 5-Step Process was BBU emulation, developed to test not only the Common Public Radio Interface (CPRI) communication link, but also the RRH functionality at the radio frequency (RF) interface, and access and test infrastructure located at the top of the tower.

In Step 3 of the 5-Step process, BBU emulation checks the ability to establish communication with the RRH. It is not sufficient to rely on a green LED on the BBU as an indication of a good optical link, as this overlooks issues such as abnormal power losses, intermittent bit errors, and incorrect CPRI link parameters. Cutting the breaker to the RRH should result in a lost connection and should be used to identify power feed connection errors.

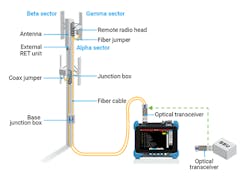

Placing the optical transceiver, a small form-factor pluggable (SFP) device (to be used by the BBU) into the test system and connecting it to the optical cable from the RRH allows the test system to establish a CPRI link, measure the strength of the optical power and check for bit errors on the uplink. The SFP from the BBU is queried to derive essential information such as supported wavelength, link rate, and distance capabilities which can be verified against acceptable limits. The SFP vendor and model number can also be verified to ensure that the manufacturer is approved and the correct part number has been fitted. At the protocol level, BBU emulation performs CPRI link negotiation to ensure the RRH supports the desired operational parameters. Performing the test using real CPRI Hyperframes, at the planned link rate for cell site operation, means results are representative of cell site performance when placed in service. (See Figure 3.)

Figure 3. BBU emulation.

Although these tests confirm CPRI uplink functionality, this does not mean that the downlink is without errors or that the RRH RF circuitry is operational. Therefore, BBU emulation offers a second level of testing using the CPRI link to query the RRH, at this stage without initializing the RF portion of the RRH (which may be disruptive to the existing cellular service). RRH SFP information is gathered, verifying downlink reliability and allowing uplink and downlink losses to be compared. RRH model and serial number as well as installed firmware are also verified against MNO requirements.

BBU emulation can now perform a third level of testing by communicating with the RRH over the Control and Management (C&M) channel running over the CPRI link. The RRH can be programmed to transmit and receive at the appropriate RF frequencies and channel bandwidth for the region in which it is installed. Control is provided over transmit power, Orthogonal Channel Noise Simulator (OCNS) and Physical Channel Indicator (PCI) values. Users can now perform additional tests on the RF side of the installation and ensure correct operation of the RF components.

Typical measurements made at traditional cell sites include voltage standing wave ratio (VSWR) and Return Loss. These indicate the efficiency, condition, and performance of the RF transmission line and associated antenna. They are now difficult to obtain as the co-ax cable is located at the top of the tower. BBU emulation performs these measurements through the CPRI link from the bottom of the tower. Returned values are displayed and compared against acceptable limits to determine a pass/fail result. As BBU emulation brings the RRH up to an operational state it is possible to see the received spectrum presented to the BBU allowing early warning to the MNO of interference issues that may exist. This might include Passive Inter-Modulation (PIM) or other external interference sources not seen from the ground. Early detection allows correction within the construction window, avoiding delays during the integration phase.

All branches of diversity can be viewed simultaneously allowing the user to detect diversity imbalance, and the ability to measure the RSSI of the incoming signal with OCNS turned on and off allows for PIM detection. A steep rise in the RSSI value when OCNS is turned on indicates that PIM may be present. Detecting PIM prior to integration allows early diagnosis of the source. Internal PIM issues require tower climbs which can be performed when the tower crew is present. External sources of PIM may require extensive work to remediate so early detection allows remedial work to take place immediately and not be the cause of a delay in cell site integration. Programming the PCI value enables the user to verify that the signal being detected over the air is coming from the desired antenna, extremely useful in DAS environments.

Checking RET Installation

RET devices allow MNOs to optimize mobile networks by changing the electrical tilt angle of the antenna. Significant errors occur when transposing information provided by the MNOs into the RET devices. Similarly, errors in transposing serial numbers of RET devices into network management systems lead to communication issues with the RET and the inability to perform antenna adjustments remotely. Correcting errors after installation necessitates a tower climb to connect to the RET.

BBU emulation identifies all devices connected to the RRH listing serial numbers for all RET devices discovered. RETs are checked for calibration, motor jams, and current tilt angle, with results stored in the database. RET tilt angles can now be adjusted from the bottom of the tower through BBU emulation.

RRHs can be brought to a fully operational state on the ground with the simple addition of an external power source (e.g., portable generator and transformer). Contractors can test all components to be assembled on the tower while they are still on the ground, avoiding mounting faulty components on the tower and facilitating easy component replacement at ground level.

Similarly, MNOs can verify defects on RRHs returned from the field prior to returning units to the manufacturer for repair, thus avoiding costs associated with No Fault Found (NFF) returns.

The last stages of cell site construction involve the connection of power by the utilities. Using a portable generator and transformer, it is possible to run the complete suite of tests on the assembled RRHs, for each sector and band, prior to connection to the electrical grid, increasing the window during which problems can be resolved without impacting the overall project timescales.

Conclusion

With shrinking budgets and skyrocketing subscriber expectations, MNOs need to seize the opportunities of the RAN transformation. Getting to revenue faster, reducing OpEx, and delivering consistently outstanding service, will be critical, and clearer insights into network performance necessities. Traditional methods of testing need to be adjusted to cope with today’s evolution towards RRHs.

A comprehensive, compact test platform with BBU emulation functionality used as part of EXFO’s 5-Step Process validates the quality of installation of new or upgraded cell sites by identifying and addressing issues with the RRHs and antennas during the construction phase allowing for seamless integration of the site into the MNOs network. (See Figure 4.)

Figure 4. FTB-1 Pro, all-in-one, comprehensive test solution.