The Optical Fiber Plant Continues to Evolve —

More optical fiber in less space. From FTTH to 5G, and everywhere in between, the message is clear: we are all using more bandwidth than ever. This also means, of course, that more fiber is being installed than ever before.

Figure 1. Placing higher fiber counts in crowded duct spaces is important for today’s network operator.

While there appears to be an infinite demand for bandwidth, there is definitely a limit in available space to deploy optical fiber. Placing more fiber in less space can be very useful for today’s network operator. (See Figure 1.)

Optical fiber rollable ribbons can roughly double fiber density versus using traditional outside plant cables, which makes these ribbons a very valuable tool in the network designer’s toolbox. In fact, rollable ribbon technology is one of the most exciting developments in outside plant cabling technology in years.

Rollable ribbons originated, and were first used, in Japan. While the concept is not new, rollable ribbons have only recently begun to be used in North America where the initial application was to connect data centers within a campus or metro area with high-fiber-count cables over short distances (up to a few kilometers). Now, interest in using this technology is expanding to other applications including FTTH, Mobility Network Backhaul, and Fronthaul applications.

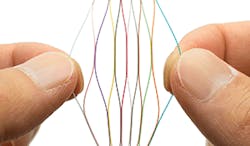

Figure 2. These ribbons are flexible and can be spliced using flat ribbon splicing techniques.

What’s the Big (or Small) Deal?

Where a flat ribbon features matrix material between the fibers and down the entire fiber length, the fibers in a rollable ribbon are attached intermittently. This configuration makes the ribbon much more flexible and "rollable". (See Figure 2.) In addition, this design enables more fiber to be installed in less space than flat ribbon cables, while also allowing the fibers to be spliced using typical ribbon splicing techniques and equipment.

In dense metro environments, many ducts are crowded. Rollable ribbon cables double the fiber density for a typical 1¼" or 2" duct, enabling thousands of fibers to go into spaces that were previously too small. (See Figure 3.)

Figure 3. This strategy can enable 2x the fiber count in a given duct size.

While greater fiber density (more fibers in a smaller space) is a key starting point, rollable ribbon technology offers many more benefits when compared to flat ribbon cables.

• Lighter weight for longer pulling/blowing distances and reduced installation costs.

• Smaller coiling diameters to fit in smaller handholes.

• Smaller cables enable longer lengths on a reel.

Longer lengths can reduce the number of splice points, splicing costs and shipping costs.

These ribbon cables are also gel-free. While removing the gel decreases the cable weight, the main benefit is to speed up and simplify the splicing process. Taking the splicing process into account, the list of rollable ribbon benefits grows even longer.

• They can be spliced using typical ribbon splicing techniques, maintaining the productivity and restoration speed benefits of ribbons.

• It is easier to break out individual fibers from the ribbon structure when using rollable ribbons.

• There is the potential to use smaller splice trays, which improves closure density, as rollable ribbons are not confined to a rigid flat ribbon structure. When compared to ribbonizing fibers in loose tube cables, it is almost impossible to cross-splice fibers in a ribbon. Cross-splicing fibers is easy to do when ribbonizing a loose tube cable, but can be very difficult to troubleshoot.

Although rollable ribbon technology is very promising, there are a few considerations that should be mentioned:

• At this point in time, rollable ribbon cables are typically more expensive than comparable options. That being said, the right design can result in some savings when compared to either standard loose tube or flat ribbon cables.

• There are some subtle operational differences between splicing rollable ribbons and flat ribbons. This fact means that there is a small learning curve involved as splicers work with it for the first time.

• Finally, cable and ribbon designs are not as standardized as more traditional designs. There are significant differences between ribbon and cable designs from manufacturer to manufacturer.

The industry is in the early days of this new type of cable deployment. Since most development to this point has occurred in Japan, it is logical that the first cable designs to be launched and promoted were more popular in Japan than in the US. Two such designs are wrapping tube and slotted core cables.

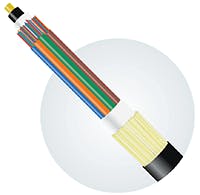

Figure 4. Rollable ribbon in loose tube designs bring many advantages.

A third design, Ribbon in Loose Tube (RILT), is a more familiar and field-proven design in North America, since several manufacturers have offered products with this structure for more than 15 years. (See Figure 4.) The fiber, ribbons, and cables, are manufactured in North America to ensure timely delivery to meet demanding project schedules.

Change Is Good

Rollable ribbon fiber optic cables are one of the most exciting developments in outside plant cabling technology in years. The benefits include smaller cable diameters and weights, along with reduced transportation and installation costs, all in a gel-free, ribbon-spliceable package.

Although initial applications have focused primarily on short point-to-point data center interconnections, rollable ribbon cables are now being considered for installations requiring frequent mid-span access such as FTTx, Mobile Backhaul, and Fronthaul applications.

Out of the available cable designs, the Ribbon in Loose Tube (RILT) cable structure offers many advantages including its outstanding suitability for use in applications requiring frequent access.

About the Author

Mark Boxer

Technical Manager, Solutions and Applications Engineering, OFS

Mark Boxer is Technical Manager, Solutions and Applications Engineering, OFS. He has more than 35 years’ experience in fiber. For more information, email [email protected] or visit: www.ofsoptics.com. You can also follow them on Twitter @ofs_optics, LinkedIn: https://www.linkedin.com/company/ofs/, and Facebook: https://www.facebook.com/ofsoptics/.