Mechanization and Robotics in the Physical Layer in FTTX Networks

Mention robots and one immediately captures the curiosity, if not the imagination, of a listener. We witnessed this real-time during OSP EXPO® 2015 when we demonstrated a mechanized optical distributing frame that we had come upon while seeking to understand the latest overseas trends in fiber loop technology. Reaction to this frame was strong, even capturing a mention during the closing keynote. Witnessing this, our own curiosity has been aroused as to how mechanization may improve management of the physical layer of FTTX networks. In this article, we share some of the possible benefits as well as some considerations regarding "robots" in The Last Mile.

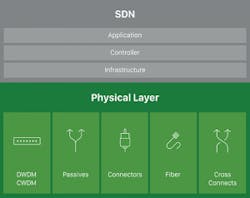

Physical Layer supports and, in effect, makes possible the SDN.

An increasing number of operators are either planning or have actually initiated a move towards Software Defined Network (SDN)-enabled networks. With these upgrades, they will receive benefits such as the automatic routing of new services along with a better utilization of deployed equipment and resources. A growing number of business cases regarding SDN indicate that significant cost savings will come with network mechanization. Further, network operators will be able to more quickly implement changes and new services to customers in intervals that are several magnitudes less than current capabilities.

SDN, of course, focuses on layers 2 through 7 as a means to effectively and automatically route data streams. An assumption is made that the necessary physical network and optical switching elements are positioned where they will be needed to take advantage of this automation.

At the same time, investment in FTTx continues to grow, largely with a focus on fiber directly to businesses (FTTB) as well as to multiple dwelling units (MDUs). In each of these scenarios, a service provider’s primary goals remain the same as they always have been: to increase revenue while simultaneously reducing provisioning and ongoing service costs.

Given these 2 networking trends, and the capital investment they require, it makes sense that operators begin to consider mechanization in the physical layer of their fiber network. In other words, as new equipment is configured, does it make sense to deploy technology such as an optical distribution frame or other devices that may be SDN-enabled and thus contribute to the cost-benefit model?

A few of the benefits that may accrue from the physical layer automation of a FTTX network include:

• Automation may help to reduce OpEx

• New revenue opportunities may be enabled with a more flexible physical layer

• End-user experience can be improved through shorter down times

• Costs associated with operators and technicians may be reduced

• Always accurate and up-to-date documentation

• Mechanized fiber management can eliminate manual errors

Automation Assists in Reducing OpEx

With mechanized fiber management and test systems in place, operating expenditures (OpEx) are likely to decrease over the entire life cycle of the network.

For example, during the build phase of a network, fiber certification and characterization can happen automatically if fiber management has been mechanized. Rather than dispatching technicians to the field to create OTDR test reports, a simple script will start automatic measurements overnight. Post-processing software will consolidate test reports (including pass/fail indication) before the technicians arrive at their office in the morning. Service activation then becomes a simple point-and-click operation, eliminating a truck roll to a remote site to make a patch.

Similarly, mechanization may contribute to efficient network upgrades by causing migration to newer transmission equipment to occur in a controlled and simultaneous way. Also, redundancy of transmission equipment can be accomplished in a very cost-effective manner, while 1:N redundancy (e.g., 1 spare for many router ports) becomes easy, eliminating the need for costly emergency interventions.

Robotic Revenue?

Today, service provisioning can be a time-consuming exercise when physical patching is required. Jobs must be planned and an available technician assigned. The tech gathers the correct material, secures access permission to the site, may sit in traffic en route to the job site, and finally reports back when the new link is established. Collectively, these tasks result in a rather long, and inconsistent, time-to-service.

Compare this to an automated patching system in which provisioning can happen in minutes instead of days. Thus, a world of new service opportunities may be opened. Just a few practical examples that come to mind include:

• Leasing dark fiber on an hourly basis

• Temporarily provisioning links during a big sports event or concert

• Bandwidth calendaring

• Mechanized switching of service providers in an open access network

• And many more

When it comes to troubleshooting, fiber optic networks are more complex than copper networks. Consider a problem in the physical fiber layer in which technicians are typically sent to the field with little information on what is wrong. All troubleshooting, faultfinding, and analysis then happens in the field. Once the problem source and locale is identified, coordination of needed resources can begin depending on circumstances (e.g., do we need to climb a pole, find a buried closure, or dig the street to get to the point of failure?).

Faultfinding and analysis move from the field to the office in a fully automated FTTX network. When trouble is detected, a new OTDR trace can be taken and compared with the reference trace established when the fiber was last automatically scanned. This allows the right person, with the right skills and equipment, to be sent to the right location immediately. As a result, the end customer will experience an improved level of service from the provider.

Streamlined Workforce

The handling of fiber optic patch cords, connector cleaning, and manual patching can be quite labor-intensive. The mechanization of these functions through a simple point-and-click operation on a computer screen will result in a need for fewer, and less specially trained, technicians. A technician is able to have full knowledge of how to control the network in days, instead of the weeks or months that is typical for the dedicated "hands-on" fiber optic training necessary for today’s technicians.

When considering higher level complex troubleshooting and faultfinding a mechanized physical layer can present great advantages. For example, the technician may use a smartphone to transmit instructions to an automated Optical Distributing Frame (ODF) to check active alarms, consult port information, take new OTDR measurements, perform an optical loss test, or even apply red light on a specific port for easy identification of the affected fiber in a splice closure. One technician can work with an unprecedented efficiency instead of using two-person crews.

Another important aspect of network management is how well equipment contributes to good record keeping. Good, accurate network documentation allows operators to troubleshoot effectively as well as to readily add new services. With automation, every manipulation of the network (provisioning, disconnection, test) may be automatically logged in management software with a date/time stamp and user ID. Records will always be accurate, drastically improving workflows across the provider’s operations.

No Manual Errors

If you have been in this business for even a short length of time, you have seen photos of manual fiber management systems that, over time, can become a tangled mass of fiber jumpers that resemble a large bowl of spaghetti. ODFs that reach such a cluttered state no longer provide the flexibility nor the capacity needed for an efficient, customer-responsive network.

An automated system ensures consistency of operations. For example, fiber patch cords will always be robotically routed in the correct way, and cable entanglement will not occur, thus exceeding the manual efforts of even the most disciplined technician. Further, cables will always be patched with the same consistent push and pull force, dust caps will always be placed, etc. In short, human errors are eliminated.

While mechanization of the physical layer of FTTX networks still appears to be a little bit in the future for most service providers, there are enough people starting to explore the possibilities here in North America that it may not be long before we begin to see robots in our networks.

[toggle title=”7 Questions to Ask Yourself” load=”hide”]Now that you’ve seen how the physical layer automation may provide distinct advantages in a FTTX environment, what’s next? First, start by asking yourself these 7 questions to decide whether the cost/benefit curves as well as appropriate technology choices are right for you.

1. Does the proposed solution replace an existing part of the fiber network, or does it merely add another potential point of failure?

2. Can the technology being considered perform such functions as characterizing and testing the fiber network without a truck roll?

3. Will the technology allow for reconfiguration of the network without deploying technicians?

4. Does the solution offer the same, or perhaps better, reliability as compared to current network elements (e.g., no signal loss in case of power failure)?

5. Does the technology use industry standard components (e.g., LC/APC, MPO, etc., connectors)?

6. What are the power requirements, and do connections remain persistent through power failures?

7. Can one expect the same optical and mechanical performance as currently used manual network elements?

Obviously, these are merely a subset of the concepts to be considered when performing a complex study on the physical fiber layer of a network. With that in mind, there are some things you can do to help prepare for mechanization of the physical layer at some point in the future.

When placing the physical layer in a new or upgraded fiber deployment, for example in an MDU, it is advisable to not "box yourself in". Use of trendy products with radically different fiber layouts or connections may seem to offer immediate benefit, but could preclude further mechanization in the future. For example, when considering new closures, choosing one that accommodates a variety of standard connectors, passives, etc., can help ensure that future network mechanization can be handled.

Also, while it may seem obvious, don’t spend more money than you need to. Dramatic overbuilding of facilities can make the challenge of mechanization even greater. As always, when planning a physical network, it’s all about return on investment (ROI), both in the immediate term as well as over time.[/toggle]

About the Author