It’s Your Time

Meet Your Deployment Milestones Even When Time is NOT on Your Side

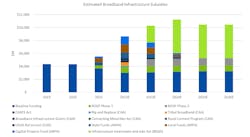

By now most of us are aware of all the funding, recently approved by the Federal Government, that will help bridge the digital divide and provide better broadband for unserved and underserved areas. (See Figure 1.) While this is great news and companies are lining up to get the funding they need, there are new considerations that must be made.

The challenge is that some of the funding requires aggressive build-out timelines and penalties for missing milestones. That means the recipients of these funds have additional pressures to meet both cost and TIME metrics as they consider how to build-out their fiber networks that require fiber distribution hub (FDH) cabinets. It also makes it imperative that network builders find a faster way to deploy fiber deeper in their networks.

This means the cassette and cassette-based fiber products introduced 15 years ago may not be as relevant to network designers, engineers, and technicians today. Even worse, they could hinder the objective of quickly building the federally funded broadband networks for which these funds have been allocated.

So how have fiber management manufacturers stepped up to provide network builders the products they need to deploy fiber faster to underserved markets?

"If you can place twice as many FDH cabinets in the time it normally takes to place them using the legacy method, it means you will be better equipped to hit your milestones when it comes to your deployment timeline."

Today’s cassette-based products help with that by offering scalability, fiber protection, and ease of use. Since their inception 15 years ago, cassettes and their associated products are well suited for a variety of applications ranging from small wall boxes to Fiber Distribution Hub (FDH) cabinets, fiber panels and even entire fiber frames. Their benefits are many, including the fact that deployment teams can train technicians on one product that is used across the entire network.

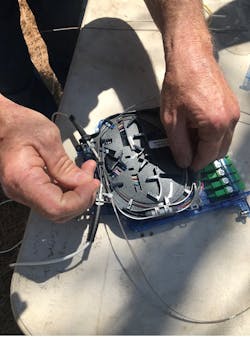

However, one key benefit of a cassette platform often overlooked is the ability to save time. Splicing inside the cassette, and the resulting proven time savings, is the next best evolution for cassette-based deployments across the board. (See Figure 2.)

Consider the multiple steps in an FDH cabinet the planner/designer needs to include in the scope of work to scale fiber networks. First, they must identify the physical location where they can procure and place the required vault, splice cases and feeder fiber cables. Once the vault is placed, a tail from the FDH cabinet is brought together with the feeder cables and spliced within a splice case inside the vault. Looking at that work function, the splicer must first roll out the FDH tail, then roll out the feeder cable and tape them together. Once that is complete, the splicer must open the feeder sheath, route it into the splice case, and prep the fibers to splice. The same procedure must be completed again with the FDH tail and distribution tails. All of this takes time. Lots of time.

This begs the question, how can the process be improved?

Looking at a typical FDH cabinet, let’s consider the time it can take a splicing crew of two to splice fiber in the field. By breaking down the work functions, we can compare placing the FDH in the traditional manner and using a process that includes in-cassette splicing. (See Figure 3.)

The traditional field method includes about three steps and can take up to 3.5 hours. The steps include:

- Open and set up handhole or utility access hole, taping distribution cable and opening sheath: 90 minutes.

- Taping feeder: 30 minutes.

- Open feeder and prep splice tray: 90 minutes.

A field method that uses in-cassette splicing requires only two steps and can take about 1.1 hours. The steps include:

- Bring feeder and distribution cables into the FDH and open sheaths: 30 minutes.

- Place buffer tubes in each cassette for splicing: 40 minutes.

It’s not difficult to understand why using the cassette as the splice tray, we eliminate the need for a splice case and even the vault in some cases.

"The challenge is that some of the funding requires aggressive build-out timelines and penalties for missing milestones. That means the recipients of these funds have additional pressures to meet both cost and TIME metrics as they consider how to build-out their fiber networks…"

If you do the math using the times above, it equates to about a 63% reduction in the time it takes to place an FDH. What does that really mean in a fiber deployment? You can place twice as many FDH cabinets in the time it normally takes to place them using the legacy method. That means you, as the network provider, will be better equipped to hit your milestones when it comes to your deployment timeline.

While this approach may still seem new to some, a direct comparison makes it easy to see why this could soon be recognized as an industry standard. Since recent federal funding emphasizes time as part of the requirements for the fiber funding you receive, you and your team are on the clock in a way that requires you to ensure your fiber deployments deliver in terms of both time and money.

ABOUT THE AUTHOR

Scot Bohaychyk is a Brand Market Manager, Clearfield. He has more than 38 years of experience in Fiber Optic design and deployment. For more information, please email [email protected] or visit www.SeeClearfield.com. Follow Scot on Twitter @Sbohaychyk and Clearfield on Twitter @ClearfieldFiber.

About the Author

Scot Bohaychyk

Solutions Manager, Emtelle

Scot Bohaychyk is Solutions Manager for Emtelle in the US and Canada. He has more than 40 years of experience in communications solutions. Early in his career in telecoms, he was assigned to the White House Communications Agency, where he provided communications infrastructure support for President Ronald Reagan and his staff both in Washington and when travelling abroad. For more information, please email [email protected] or visit www.emtelle.com.

You can also follow Scot on Twitter: https://twitter.com/Sbohaychyk. Follow Emtelle on Twitter: https://twitter.com/EMTELLE, LinkedIn: https://www.linkedin.com/company/emtelle/, Facebook: https://www.facebook.com/Emtelle, and YouTube: https://www.youtube.com/user/Emtelle1.

Emtelle is opening a new facility in Fletcher, North Carolina, in 2023.