What You Need to Know for Successful Deployments —

When power over Ethernet (PoE) was first introduced in 2003, the original IEEE 802.3af standard supported the delivery of up to 15.4 Watts (W) of safety extra low voltage (SELV) DC power over twisted-pair network cabling, referred to as Type 1 PoE. This was ideal for powering low-voltage IP-based network devices such as Voice over Internet Protocol (VoIP) phones, early generation Wi-Fi access points, and IP clocks. As PoE deployments grew in popularity, the ICT industry realized the benefit of eliminating material and labor cost to deploy separate AC power circuits to devices, while improving safety, reliability, and flexibility.

PoE technology has since advanced to now include Type 3 PoE that generates 60W and Type 4 PoE that generates 90W from power sourcing equipment (PSE), providing up to 51W and 73W of input power respectively at the powered device (PD). The ability to deliver these increased levels of power to IP-based network devices over the same cabling that transmits data has opened a huge realm of possibilities. PoE is now commonly deployed for powering everything from laptops, digital displays, and point-of-sale machines to surveillance cameras, door access systems, and facility-wide LED lighting.

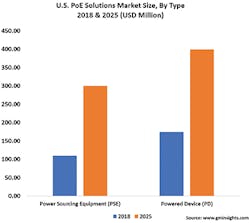

With the adoption of LED lighting systems and the number of IoT-connected devices continuing to soar, projected by Gartner to potentially reach as high as 75 billion devices by 2025, PoE deployments will inherently follow suit since a significant portion of these devices will be PoE compatible. This is why

Navigant Research expects the PoE market to grow at a rate of nearly 15% over the next few years. (See Figure 1.)

Figure 1. Navigant predicts that the market for PoE products will grow at an annual rate of 15% over the coming years.

Given that anyone deploying and managing ICT systems today will more than likely need their cabling plant to support PoE, understanding the requirements and key considerations for installation, testing, and troubleshooting, can go a long way in ensuring success.

Heat Rise Considerations

When cables carry PoE, the temperature within the cable rises, as does insertion (i.e., signal) loss. The higher the power level and smaller the gauge of the cable, the more the cables heat up. In large bundles of cables, it is difficult for this heat to dissipate. Cables located in or near the middle of the bundle can heat up to the point that the loss of signal can prevent proper data transmission. This can be especially concerning in higher temperature environments, such as above the ceiling in very hot climates — and it can be catastrophic for mission-critical devices.

To address the issue, TIA and ISO/IEC standards provide guidelines on how to minimize temperature rise and the National Electric Code (NEC®) requires that cables carrying more than 60W of power comply with bundling requirements. Section 725.144 of the NEC includes ampacity tables for 4-pair cables that provide recommended bundle sizes based on the temperature rating and gauge of the cable, as well as the ampacity (current expressed in amperes) carried by each conductor in the cable.

Using the ampacity tables can be a tad confusing but this can be avoided by not bundling cables during installation or by deploying LP-rated cables that are listed by UL as suitable for carrying power and data circuits up to their marked ampere limit for each conductor without exceeding the temperature rating of the cable.

If LP-rated cables and avoiding bundles are not an option, or you are simply in doubt about the cable’s heat dissipation capability, ambient temperature of the environment, or the level of PoE power to be delivered once the installation is complete, a good rule of thumb is to keep bundle sizes to 24 cables. If you keep the number of cables in your bundles at 24, cables that are 24 AWG or larger with a minimum operating temperature of 60°C (i.e., typical for most category twisted-pair network cables) will not cause an issue in most installations.

InvisiLight® Solution for Deploying Fiber

April 2, 2022Go to Market Faster. Speed up Network Deployment

April 2, 2022Episode 10: Fiber Optic Closure Specs Explained…

April 1, 2022Food for Thought from Our 2022 ICT Visionaries

April 1, 2022The Right Test Parameters

PoE is transmitted by applying a common-mode voltage on either 2 pairs (Type 1 and 2) or 4 pairs (Type 3 and 4) of a twisted-pair cable — meaning the current is evenly split between the 2 conductors of a pair. For this to happen, the DC resistance of each conductor in the pair and between multiple pairs must be balanced (equal), and any difference is referred to as DC resistance unbalance.

While PDs can tolerate some DC resistance unbalance, too much unbalance causes saturation of the internal signal transformer, which causes it to stop working as a transformer. When this occurs, the waveforms of Ethernet data signals become distorted, causing bit errors, retransmits and even nonfunctioning data links.

While inferior quality cable with variations in conductor diameter and concentricity (roundness) are at a higher risk of DC resistance unbalance, improper terminations can also cause DC resistance unbalance. The best way to ensure good DC resistance unbalance performance for support of PoE is during field testing. So, ideally anyone conducting compliance testing after installation should use a tester capable of testing for this parameter both within a pair and between pairs.

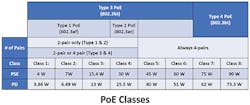

Understanding (and Verifying) the Class

IEEE 802.3 PoE assigns classes to a PoE system, whereby the class is determined by the lowest common power level that can be supported by both the PSE and PD. (See Figure 2.) This is achieved by the PSE detecting the power requirements of the PD.

Figure 2. The IEEE’s 3 PoE standards define 3 types of delivery methods and 8 power classes.

The various classes range from 0 to 8 with:

- Type 1 and Type 2 PoE encompassing Class 0 through Class 4, which covers input power at

the PD ranging from 3.845W to 25.5W. - Type 3 includes Class 5 (up to 40W at the PD) and Class 6 (up to 51W at the PD).

- Type 4 includes Class 7 (up to 62W at the PD) and Class 8 (up to 73.3W at the PD).

The main reason for a class system is to allow power requirements to be negotiated for better management of the PSE’s power budget. For example, if the PSE is Class 6, but the PD is only Class 5, the system is classified as Class 5, and the PSE can set the maximum power delivered to match the requirements of the device, rather than providing more power than is required.

A key to ensuring proper support for PoE is to ensure that the class number of the PSE is equal to or greater than the class of the PD. An easy way to accomplish this is with a network tester that, when connected to the PSE, has the ability to display the class (0-8) of power available on the link. That information can then be compared to the requirements of the PD to know if the power required is available.

This is also ideal for moves, adds, and changes. For example, if a Class 4 PD is later replaced with a Class 6 PD, then having the ability to display the power class on the link verifies if the link will support the new device.

PoE Load Testing Is Ideal for Troubleshooting

Figure 3. The tester displays the power class and wattage advertised by the PSE, and loads the circuit to ensure that the power is actually available.

While following cable bundling requirements, ensuring DC unbalance resistance performance, and verifying PoE class on a link can certainly ensure successful PoE deployments, problems can still arise — especially if the advertised power capabilities of a switch is not what is actually being delivered. This can occur if the overall power budget on a PoE-enabled switch has been oversubscribed.

Network testers like Fluke Networks’ LinkIQ™ have the ability to not only verify PoE class but can also receive link layer discovery protocol information from a switch and place a load on the connection. (See Figure 3.) This allows a technician to display the pairs where power is provided, the power levels, and results of the PoE test under load, to ensure that the advertised power is actually being delivered by the switch across the cabling.

PoE is here to stay, and becomes only more ubiquitous as the number of connected devices continues to increase. Understanding the installation considerations and having the right testing and troubleshooting tools ultimately becomes an absolute necessity for ICT professionals.

For more information, please email [email protected] and visit https://www.flukenetworks.com/.

Follow Mark on Twitter @FlukeNetDCI.

Follow Fluke Networks on Twitter @FlukeNetworks.

Like this Article?

Subscribe to ISE magazine and start receiving your FREE monthly copy today!

About the Author