Latest from FTTx/Optical Networks

Technician Challenges/Solutions in 2018 —

New technologies bring with them new challenges. This article focuses on a couple of key topics that will be crucial to fiber optic technicians this year, as well as solutions to some of these issues.

While all fiber optic communication systems are affected by signal attenuation, optical dispersion, and optical reflections, older fiber systems need special attention when implementing higher-speed transmission protocols. Early system testing and equipment focused mostly on measuring attenuation levels at 1310 and 1550 nanometers with an optical time domain reflectometer (OTDR) or an optical loss test set (OLTS). Legacy installations present 4 major challenges for modern systems:

1. Older systems are much less sensitive to reflections.

2. Older fiber has tolerances that limit low loss splices.

3. Most have never been tested at longer wavelengths, as recommended by the ITU.

4. Many have low fiber count cables installed.

Let’s take a deeper look at each of these challenges and what, if anything, technicians can do to rectify the problems.

Challenge 1. Reflection

Today’s systems operate at much higher data rates — rates at which measuring reflectance has become just as important as measuring attenuation. In the 1980s and early 1990s, terminations had reflection levels of 40-45 dB and spherical physical contact (PC) and super physical contact (SPC) polishes. Contemporary terminations use ultra physical contact (UPC) and angled physical contact (APC) polishes, which have lower reflectance levels (55-65 dB).

The term reflectance is used to describe the signal loss at single component. Most common reflectance problems are caused by the abrupt changes that take place at connections, mechanical splices, or at the ends of fibers. These Fresnel reflections are one of the limiting factors in achieving acceptable bit error rates (BER).

Optical return loss (ORL), on the other hand, is the sum of all of the reflections in the entire span, including the fiber’s intrinsic Rayleigh backscatter and all the Fresnel reflections. ORL values are specified by system manufacturers to verify that the transmission equipment will meet the required BER.

If the measured value exceeds the rated value during ORL testing, the first step is to identify which of the component’s Fresnel reflection is too high. Fortunately, an OTDR can easily perform both ORL and reflectance tests. Once the test is performed and the component with high reflectance is identified and replaced, the span should be retested and the new values documented.

Figure 1. Single-mode fiber with splice-on SC/APC connector.

By performing proper reflection testing with an OTDR, any out-of-spec legacy terminations can be identified and replaced with splice-on connectors to achieve lower reflectance levels. (See Figure 1.) Or, if a splice panel is available, factory-terminated pigtails can also be installed.

Challenge 2. Fiber Tolerances

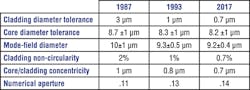

Many attenuation issues are the result of intrinsic fiber tolerances. Fiber geometries have changed a great deal over the decades, and these changes in tolerances can lead to older splices with losses as much as 0.5 dB. (See Figure 2). Differences in the diameters of the fiber’s core, cladding, and mode field, its ovality, or the core/cladding concentricity, can add unwanted loss into the system.

Figure 2. Fiber tolerances over the years.

While fusion splicers have improved tremendously over the last 25 years, they cannot resolve fiber tolerance mismatches. Therefore, it is important to recognize that while older splices can be reterminated to potentially improve the splice value, it is likely the fiber tolerances that are preventing splices in the 0.1 dB range.

Even the best technicians with the best equipment cannot resolve attenuation loss from fiber tolerances. Therefore, the splice values cannot be specified to unobtainable levels.

Challenge 3. Longer Wavelengths

A current trend in optical communications is the assignment of longer wavelengths for transmission, especially in fiber-to-the-home systems. The ITU-T G.989 WDM-PON standard specifies wavelengths up to 1625 nm, dense WDM now operates up to 1577 nm, and, in many cases, "out of band" handshaking is occurring at 1625 nm.

Because fiber has increased sensitivity at longer wavelengths — which is why testing at 1550 nm easily identifies macrobends and microbends — the ITU has issued several recommendation standards to address maintenance and testing.

The ITU-T L.40 document Optical fibre outside plant maintenance support, monitoring and testing system addresses options for testing dark and in-service fibers.

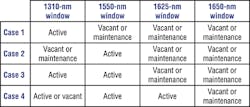

"Out of band" testing is defined by the ITU L.41, Maintenance wavelength on fibres carrying signal. This document defines available wavelength options and simultaneous monitoring of installed spans with minimal impact. As shown in Figure 3, worst-case testing occurs at 1650 nm (i.e., a dense WDM system operating in the 1550 nm C-band with handshaking occurring at 1625 nm).

Figure 3. ITU-T L.41 maintenance wavelength assignments.

Challenge 4. Fiber Counts

Cables with low fiber counts must either be replaced with higher fiber count cables, or multiplexing must be implemented. Limitations in fiber counts require higher levels of multiplexing, whether electrical or optical. Should some form of multiplexing be employed, a new level of test equipment and tests must be performed, requiring greater knowledge and skills training. In these cases, analyzing specific wavelengths and optical signal-to-noise ratio (OSNR) will be necessary, as well as the possibility of optical amplifiers. In addition, technicians must be attentive to quickly resolving reflection problems.

Remain Relevant

The role of the fiber technician continues to evolve to keep up with changing technology and the impact of higher speed transmission systems. Technicians must stay current on advancements in testing equipment, how they work, and how and where to properly test and troubleshoot. Testing for component reflectance and span ORL using an OTDR is now equally as important as performing splice and fiber attenuation measurements. Knowing how to test installed fibers is critical to achieve the bit error rates required for new high-speed systems.

Given the correct training and tools, technicians will continue to install, maintain, and troubleshoot, the fiber optic communication systems for today and the future.