Latest from FTTx/Optical Networks

Proactive Powering Problem-Solving with Polymers

Lowering Optical Modulators’ Power Consumption

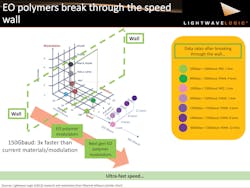

Optical modulators are used in huge volumes everywhere a laser sends light down a fiber optic cable. Today, they are built from semiconductor materials such as silicon and indium phosphide. Unfortunately, these semiconductor materials are suffering from a saturation of performance (as shown in Figure 1). They are struggling to handle the ever-increasing demand for higher data rates, and when they do, they do it with increased power consumption—which is something Internet operators are looking to mitigate quickly.

Improving this optical networking component is critical to helping network designers find ways to deliver data faster and with lower power consumption. This is important not only for next-generation telecom and datacom equipment (such as routers, servers, switches, etc.), but for equipment planning over the next decade (or more).

Thankfully, newer modulators created from specially designed electro-optic polymers are naturally fast, and naturally low power in their design. These properties are giving network designers a new opportunity to design optical networks.

The impact of a faster and lower power electro-optic modulator can have far reaching effects in today’s world where industry, corporations, and manufacturing require higher data rates. The modulator allows easier access to higher quality data flow, which in turn permits a higher quality of information and more efficient product development.

Lowering Power While Meeting Demands

While consumers want more speed for our personal or professional use, the mantra to lower power consumption is key for datacenters today and where they are heading over the next decade. Both speed and low power have become important design criterions for next-generation network architectures that are expected to evolve in coming years. This is forcing optical network architects and optical network planners to rethink their technology strategy. They are being pushed into figuring out how to increase the optical device speed without the use of very expensive and complex electronics. Even though this was unimaginable a few years ago, it has the realty today.

Network architects are currently using expensive and complex integrated circuit (IC) chips at the 5nm and 7nm node levels, which consume a lot of power just to be able to send data quickly. The simple solution is to increase the speed of the optics, and while this sounds easy and obvious, it is actually difficult and has been especially so with the use of semiconductor-based optical modulators. This is where polymer optical modulator devices have a huge impact, switching light much faster and at a lower power consumption than existing optical semiconductor devices. This relieves the network architects of expensive and power-hungry electronic ICs.

The industry has been on a plateau of modulator device speed (around 25-40GHz electro-optical bandwidth) using semiconductor optical modulators running at voltage levels ranging around 3-30 volts for the past couple of decades. As data rates have increased (just a few years ago our modem rates were 1kbps or 1,000 bits per second and now our Internet speeds are 1Gbps or 1,000,000,000 bits per second; or over a million times faster), so has the power consumption. The industry has employed a technique using electronics to allow the optics to go faster by increasing the number of symbols per bit: i.e., with pulse amplitude modulation at 4 levels (PAM4), a method that is popular today. This allows speedier data rates at a cost: it drives the power consumption levels extremely high, which can cause significant thermal issues.

Impact of High-Performance “Vehicles”

Datacenters, telecom switches, and the fiber optics industry in general, are becoming more and more focused on how to bring power consumption down. They simply must, as these services are now significant in the use of electrical grid energy in the US. At the network equipment level, the higher data rates are placing a significant burden on servers and routers, in that data needs to be communicated via fiber into and out of these systems. One popular place where the data flows is the rack-based faceplate, the place on the front of these systems where many pluggable optical transceiver modules are positioned to transduce optical signals from fiber into the electronic switch blades (and vice versa).

A pluggable optical transceiver is a tiny box that plugs into the network equipment. There are millions of them all over the optical network for telecommunications and data communications. The pluggable optical transceiver converts the optical signals into electrical signals, so that the electrical signals can be switched, routed, and directed to their destinations in the network.

A good way to visualize the pluggable optical transceiver tiny box is as a vehicle on an interstate highway. Some vehicles, as we know, have more powerful engines that allow them to operate at faster speeds, and others, such as electric vehicles, are designed for lower power consumption. Electro-optic polymers are like putting in a high-speed engine that operates with lower power into the pluggable optical transceiver vehicle. Having high-performance engines that fit snuggly into pluggable optical transceivers, positions electro-optic polymers to scale quickly and efficiently into the optical network architecture.

Even as the industry looks to innovate with its incumbent and classic “vehicles” such as pluggable optical transceivers, there has been a new trend to look at on-board optics (OBO) or co-packaged optics (CPO). These are innovative designs that essentially circumvent the pluggable optical transceivers at the faceplate, to increase more data flow in and out of the line cards and network equipment. Either way, the drive to high-speed, lower power, and miniaturization is real.

However, there is limited volume or footprint for either of these solutions to be part of the network equipment since space is increasingly restricted. The interest and pull from the networking giants to integrate and miniaturize these photonics vehicles has been steadily increasing over the decade. We are now at a point in time where the opportunity for a sunrise technology—electro-optic polymers as high-performance optical engines—can replace a sun-setting semiconductor optical modulator technology that is struggling to achieve the demands of network architects over the next decade.

“The simple solution is to increase the speed of the optics, and while this sounds easy and obvious, it is actually difficult and has been especially so with the use of semiconductor-based optical modulators. This is where polymer optical modulator devices have a huge impact, switching light much faster and at a lower power consumption than existing optical semiconductor devices. This relieves the network architects of expensive and power-hungry electronic ICs.”

Scaling Electro-Optic Polymers

Electro-optic polymers can be manufactured in large silicon foundries. These are fabrication plants that focus on silicon semiconductors and have traditionally set up their process design kits (PDKs) for ICs. Over the past few years, many silicon foundries have been looking at increasing their wafer throughput by servicing silicon photonics solutions. It is these foundries that are the catalyst for volume scale when polymers are added to silicon photonics.

To have polymer modulators ubiquitous across the industry, key milestones are being achieved at record pace: advanced and mature electro-optic polymers, simple and standard fabrication in large scale volume, and packaged modulator devices as part of the high-performance “vehicle” with pluggable optical transceivers. The polymer industry for fiber communications is growing quickly. With the correct positioning for scale, volume, and performance, electro-optic polymers are poised very well to enable and scale the Internet and optical network architectures to be much more competitive in the near future.

Dr. Michael Lebby | CEO, Lightwave Logic

Dr. Michael Lebby is CEO, Lightwave Logic. He has more than 40 years’ experience in optoelectronics, electronics, and semiconductors with a particular focus in integrated photonics. For more information, email [email protected] or visit https://www.lightwavelogic.com. Follow them on LinkedIn: https://www.linkedin.com/company/lightwave-logic-inc-/.