Latest from Automation/AI/AR/VR/Chatbots

Year-End Pledge: Zero Wait, Zero Touch, and Zero Trouble

CSPs Must Accelerate Autonomous Networks Adoption

Today, companies across all industries are rushing to define and implement better digitally enabled business models. A survey by the World Economic Forum found that 80% of companies intend to digitize their processes as soon as they can.

The rate of transformation is unprecedented. A study by McKinsey & Company showed that “increasing the use of advanced technologies in business decision making” takes 25.4 days, compared to the 635 days it takes in normal times. (Source: www.mckinsey.com)

At the forefront of improving digitization are the service providers that deliver the underlying connectivity, hosting, and compute infrastructures for the underlying infrastructure needs of their customers. Cloud and edge computing, the secure and fast transport and processing of big data, IoT enablement, the delivery of Virtual Reality and Augmented Reality capabilities, cybersecurity, blockchain and others are some of the capabilities the service providers need to deliver at scale, with high reliability, velocity, elasticity, and flexibility in the future.

Delivering these capabilities and others will not be possible with manual, siloed infrastructure. Thankfully, CSPs have started implementing software-based infrastructures, and many have introduced automation capabilities across their networks and operating environments. However, the scale and complexity of what Industry 4.0 will require far exceeds the capabilities of most, if not all, CSPs today.

A new framework is required. This framework relies on pervasive intelligence and automation; it demands a communication and an operating infrastructure that is a fully automated network that is self-healing, self-managing, and fully reliable.

Of course, network automation is not a new concept, and most operators have already implemented some level of automation in their networks and operating environments. However, the level of automation currently in place is inadequate for the requirements of the market going forward. It is increasingly obvious that the market needs a much more comprehensive and pervasive level of automation in network infrastructure powered by intelligence implementation. The new level of automation must handle closed-loops as well as the capability to support full-cycle automation, enabled by AI. This level is referred to as Autonomous Networks (ANs).

ANs are becoming an essential goal for every CSP and will be table stakes for success in a fast-transforming market as they become the bedrock of digital industries. Today, operators are in a better position to move toward ANs:

- Market forces are making ANs essential, and the pace of change is creating business opportunities for CSPs to grow revenue by offering end-to-end services across verticals.

- Many of the impediments to achieve ANs are being mitigated by advances in technology.

“A study by McKinsey & Company showed that ‘increasing the use of advanced technologies in business decision making’ takes 25.4 days, compared to the 635 days it takes in normal times.”

Use Case: Manufacturing

Automation and data transformed into actionable information are the major enablers of Industry 4.0. These capabilities are considered essential for the transformation of the manufacturing and industrials because they are already experiencing significant change.

Although each vertical has its own ecosystems, operating goals and KPIs, applications, and customer needs, an underpinning requirement is the gathering and storage of data, the reliable movement of that data, high speeds over a versatile communication infrastructure, and the ability to dynamically adapt to changes in the business environment.

For manufacturing to digitize, information barriers that today exist across the ecosystem need to come down, processes need to be redesigned on the fly because of supply chain issues or to the need for modification to improve safety or adapt to unforeseen manufacturing issues. Data needs to be collected and analyzed in real time to inform on-going processes and adapt in real time while providing maximum visibility to enable preventive remediation, process improvement, and training.

Major automotive manufacturers such as GM, Toyota and Tesla have been automating their assembly plants and operations using robots and have been introducing data analytics into their supply chains, resulting in innovations such as just-in-time production. These advances have led to more flexibility and agility in adapting to demand shifts while reducing waste.

The major technologies enabling Manufacturing 4.0:

- Augmented Reality: Example use cases include training, visualizing a finished product, and identifying unsafe work conditions. Text, stats, and images can be overlayed to augment the current work environment, providing invaluable real-time information to the workers and improving decision making, processes, and safety.

- Virtual Reality: Enables real-life simulations of production environments, processes, and configurations—identifying potentially dangerous situations. It allows employees full immersion in a real-life environment for training or for task design or modification.

- Robotics: Robotic automation is playing a large part in manufacturing, performing tasks such as welding, assembly, shipping, and handling raw material. Robots are working side by side with humans, leading to cost reductions, quality improvements, and improved productivity.

- Machine Learning and Artificial Intelligence: Allows for the collection of data from multiple sources and analyzing it in real-time with far-reaching improvements in manufacturing—predictive fault remediation, preventive maintenance, improved forecasting, optimizing robotics, and real-time monitoring.

- Digital Twin: This virtual representation of a real-life component or asset enables manufacturers to test multiple solutions before introducing the optimal one or to assess the impact of changing sourcing decisions on operations and costs. Boeing is a major user of this technology for aircraft design.

- Industrial Internet of Things: IoT largely focuses on connecting thousands of machines and devices in an industrial setting. It enables companies to instrumentalize production lines, making them able to track and analyze processes and track assets at a very granular level, enabling better efficiencies, predictive maintenance, and cost savings.

- Cloud and Edge Computing: Given the significant amount of data processing generated by IIoT and other technologies, companies will need compute capabilities in various locations based on the particular requirements of the tasks at hand.

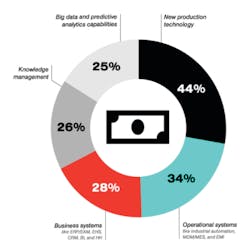

- Advanced Engineering: This uses 3D printing and other additive manufacturing techniques for rapid prototyping, speeding manufacturing, and reducing costs. (See Figure 1.) Complementing these technologies are agile development processes linking intelligent factory and product feedback into connected product engineering and development teams that are leveraging the digitized infrastructure in delivering their enhancements.

Data convergence, IIoT and analytics are the technologies driving major improvements and revenue growth in manufacturing as they connect systems and integrate data, move away from current silos, automate processes to reduce errors, improve quality, and provide better tracking and traceability. Enabling these capabilities are networks that need to be extremely reliable, responsive in real-time, fully, and automatically adaptable to changes in rather complex environments.

Achieving the promise of Industry 4.0 requires a complete transformation of the enterprise toward a digital operating model where employees design and oversee a software-automated, algorithm driven digital organization that delivers the goods. At the heart of this enterprise is an AI factory that provides the underlying capability for data gathering, analytics, and decision making. This organization is modular or composable; it requires a new communication infrastructure that enables modularity, flexibility, scalability, and velocity. ACG Research has recently defined the concept of Intelligent Composable Fabric, which contains operations, information, and communications technology modules that flexibly compose the intelligent digital operations platform of an enterprise. This fabric requires a communication infrastructure that is zero wait, zero touch, and zero trouble (Zero X). Such an infrastructure can only be delivered by ANs.

Although there are multiple levels of automation, the truly digital enterprise is only realized at the maximum level of automation or full automation where the system possesses closed-loop automation capabilities across multiple services, multiple domains, and the entire life cycle. Only in this case can Zero X be realized.

At the heart of ANs are autonomous domains that form the basis for closed-loop automation. They expose network capabilities that can be used by the enterprise without exposing the complexity, enabling the enterprise to define business rules and to use the capabilities as needed and when needed by the business on a modular level. These capabilities are self-assuring, providing maximum reliability to the business.

As AI becomes the run time of the digital enterprise of the future, the firm will be rearchitected to leverage the power of data, networks, and AI. This is only possible when the underlying network infrastructure delivers the resiliency, scalability, and automation that is enabled by ANs.

“...many have introduced automation capabilities across their networks and operating environments. However, the scale and complexity of what Industry 4.0 will require far exceeds the capabilities of most, if not all, CSPs today.”

The Bottom Line

The pandemic ushered in digital acceleration on an unprecedented scale and scope. Although some of the changes were short-term focused, meant to blunt the impact of the pandemic, the crisis caused leaders in every industry to rethink their business models, with digital enablement front and center to their strategies.

Digital enablement is the foundation of this transformation, and this foundation has to be powered by a network that is autonomous, ultra-fast, extremely reliable, flexible, and highly scalable. That AN is the only route to achieve this transformation because it enables the diversity, agility, dynamic scalability, and security requirements of Industry 4.0.

Now is the time for the AN, which is not simply the next thing; it is essential to enabling the world to deal with shocks, to deliver the dynamism that will be needed in every industry going forward.

The business conditions are ripe, but the technology has also evolved to a point where this premise is now possible and indeed realizable. Innovative CSP vendors are already introducing AN solutions, and CSPs are beginning to draw plans with their vendors and partners to evolve their technology and business models to make ANs a market reality.

ABOUT THE AUTHOR

Liliane Offredo-Zreik is a principal analyst with ACG Research. Her areas of coverage include the cable industry, SD-WAN, and digital transformation. Prior to her analyst work, she held senior roles in major telecom and cable companies, including Verizon and Time Warner Cable (now Charter).

Thank you to Liliane’s ACG colleague, Mark Mortensen, for his significant contributions to the original paper and ACG Research’s, “Autonomous Network Power Industry 4.0”.

For more information, please email loffredo@acgcc.com or visit www.acgcc.com.

Follow Liliane on Twitter: https://twitter.com/offredo and LinkedIn: https://www.linkedin.com/in/lilianeoffredozreik/.

Follow ACG Research on Twitter: https://twitter.com/acg_r/ and LinkedIn: https://www.linkedin.com/company/acg-research/.

Liliane Offredo-Zreik | Principal Analyst, ACG Research

Liliane Offredo-Zreik is a principal analyst with ACG Research. Her areas of coverage include the cable industry, SD-WAN, and digital transformation. Prior to her analyst work, she held senior roles in major telecom and cable companies, including Verizon and Time Warner Cable (now Charter).

Thank you to Liliane’s ACG colleague, Mark Mortensen, for his significant contributions to the original paper and ACG Research’s, “Autonomous Network Power Industry 4.0”.

For more information, please email loffredo@acgcc.com or visit www.acgcc.com.

Follow Liliane on Twitter: https://twitter.com/offredo and LinkedIn: https://www.linkedin.com/in/lilianeoffredozreik/.

Follow ACG Research on Twitter: https://twitter.com/acg_r/ and LinkedIn: https://www.linkedin.com/company/acg-research/.